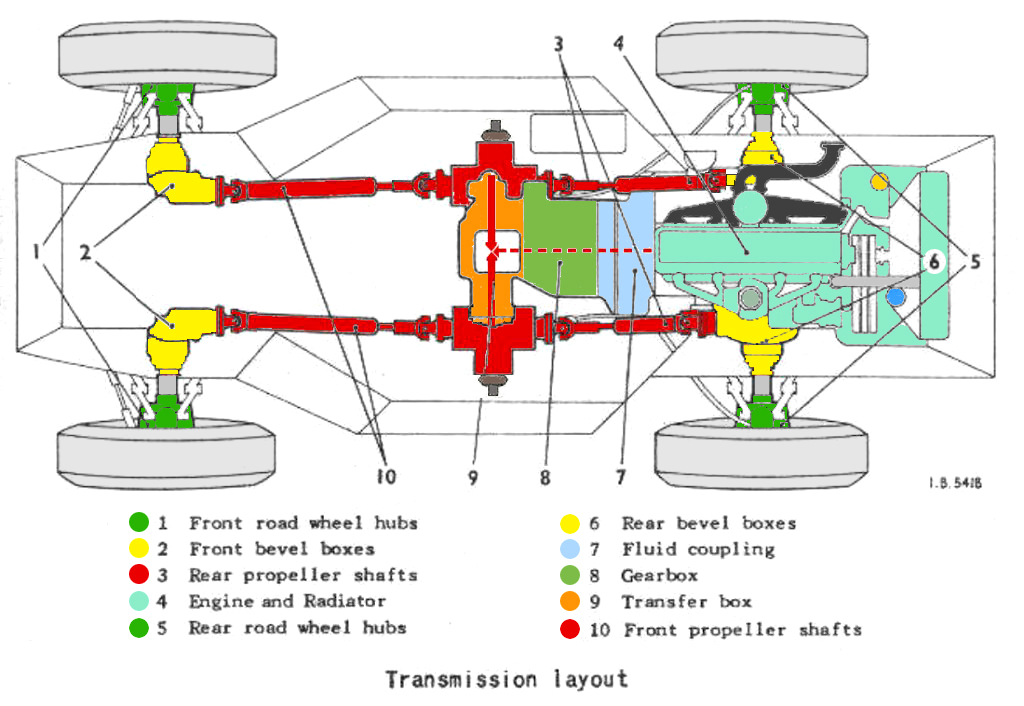

The Ferret was a popular and efficient vehicle in Army service. Its only weakness is generally considered to be the potential for wind-up, due to the fact that it is a permanent four-wheel drive. The Ferret has a single H-differential and thus a virtually a solid connection between its front and back wheels on each side. Wind-up will happen on hard surfaces and sealed roads. Hitting the wheels on the dirt or gravel roadside occasionally only relieves wind-up between nearside front and rear, unless you can get all four wheels off the road.

When a car corners, all four wheels rotate at different speeds since each follows a different imaginary circle. The two wheels on the inside of the turn rotate slower than the pair on the outside, for they follow a smaller radius circle. The front wheels must rotate faster than the rear ones, for they follow a larger radius circle. For best traction both front and rear wheels ideally should propel the vehicle. Therefore a differential or transaxle (a combined transmission and differential) is required, to allow differing rotational speeds. Without a differential either the inner wheel rotates too fast or the outer wheel drags, which results in difficult and unpredictable handling, damage to tyres and strain on, or possible failure of, the entire drivetrain.

Try and catch potholes, manhole covers and catseyes to give the wheels bumpiness, allowing them to unwind. Constant ‘circular’ driving – even if it is not tight circles (e.g. constant left-hand/right-hand turns) will result in wind up. Vary the route all the time. Take the opportunity to go over uneven ground, bumps, potholes, manhole covers and sleeping policemen.

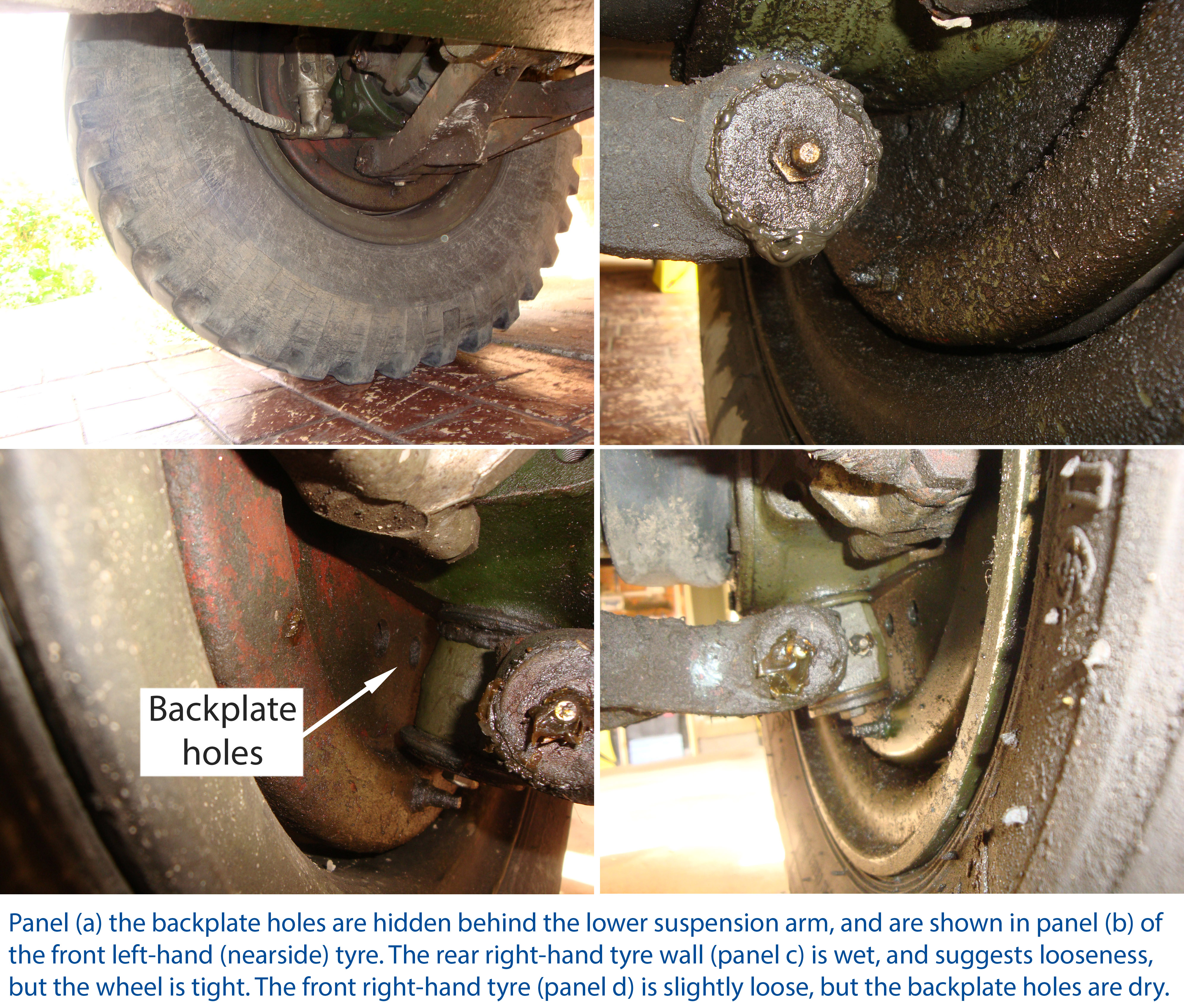

I’ve spray-painted hour clock hands on my wheel hubs easily to keep a useful check on transmission wind-up. This practice was never official, but sometimes you’ll see photos of a Ferret in service with a line painted across the diameter of the wheel hub. If the wheels on each side gets really bad and the lines are not parallel, I’ll jack up both wheels on each side, one side after the other, to relieve wind-up tension (ensure the other side is chocked!). The first sign of a loose wheel is usually a wet tyre on the inner side-wall from EP-90 seeping out of the hub/’wet axle’.

Another cause of wind-up hard learned: pay attention to tyre pressures! I had an inner tube that had not only deflated but had wound onto the wheel hub within the tyre. Normally the inner tube valve sticks out from the tyre by about 2 inches, or so (see here). In this case, the valve had disappeared inside the slot in the wheel. The only way air could be pumped in was to remove the wheel and pump from the inside face. Time for a new inner tube. I use Sutton Courtenay Tyres – they are local and first-class. The reason the front wheel became loose was the tyres on each side are linked and because the tyre diameters differed (the handbook recommends no more than a 2″ difference in diameter). The front wheel stations are usually more susceptible to wind-up, and in the case the rear deflated tyre dragged on the front one, causing loosening from wind-up. The handbook states 30 psi at the front, and 36 psi for the rear tyres. The Daimler Ferret Owners’ Club recommends 5 psi over these values: 35 front/41 rear – but watch for sidewall cracks on these old tyres. Hard inflated, the wheel is then much more likely to skip over the road surface and unwind. I keep them at 45 psi all round (see maintenance schedule).

Inspect the backplate holes, which lie beneath where the hub housing joins the backplate, below the centre line. If oil is running from these, then the hub seal is leaking, the wheel is loose and the wheel station needs attention. If, on the front wheels, the backplate holes are dry and there is still a tiny amount of fore-aft play on the jacked-up wheel, then its due to the swivel joint and cannot be eliminated. You can’t stop all the oil coming out, so you just need to top up the wet axles. Providing the hub seal is OK, the wheel station is OK.

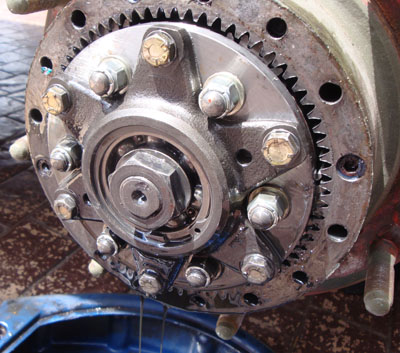

Whilst in service wind-up was not generally a problem. Checks for slackness were carried out every 500 miles and the local REME workshop could quickly repair any loose wheels. With fewer parts now available, it is more of a challenge for civilian owners. The dowels and bolts that work loose with wind-up can be seen in part (4) of this picture of the epicyclic reduction gears. This page explains how the transmission of the Ferret is constructed, and how wind-up occurs. You’ll also find an illustrated protocol showing the repair of a wheel station.

Repairing the wheel station

andOil seal informationCourtesy of M Jones